OptiProd AI

Heuristics + AI for sequencing, SMED and supply planning.

Detects bottlenecks and proposes prioritized actions using genetic algorithms, neural networks and AI.

Automate, connect and optimize your plant with intelligent agents, digital twins and secure interconnection solutions between information systems.

Explore our solutions

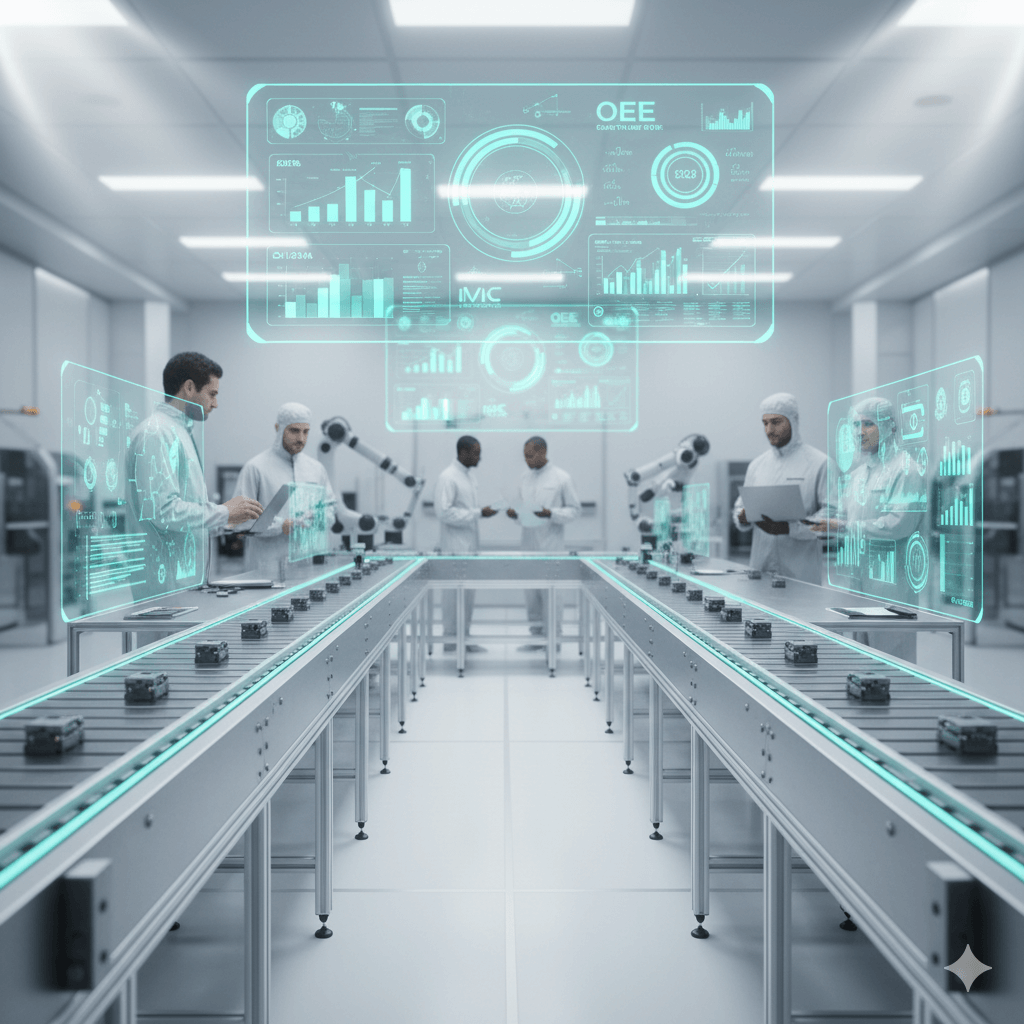

We maximize throughput and OEE: removing bottlenecks, stabilizing rhythms and reducing losses.

Detects bottlenecks and proposes prioritized actions using genetic algorithms, neural networks and AI.

Availability, performance and quality with alerts and daily reports connected to an AI agent.

Predictive agent for inventory control and replenishment. Integrates ERP data, forecasts and optimal replenishment policies.

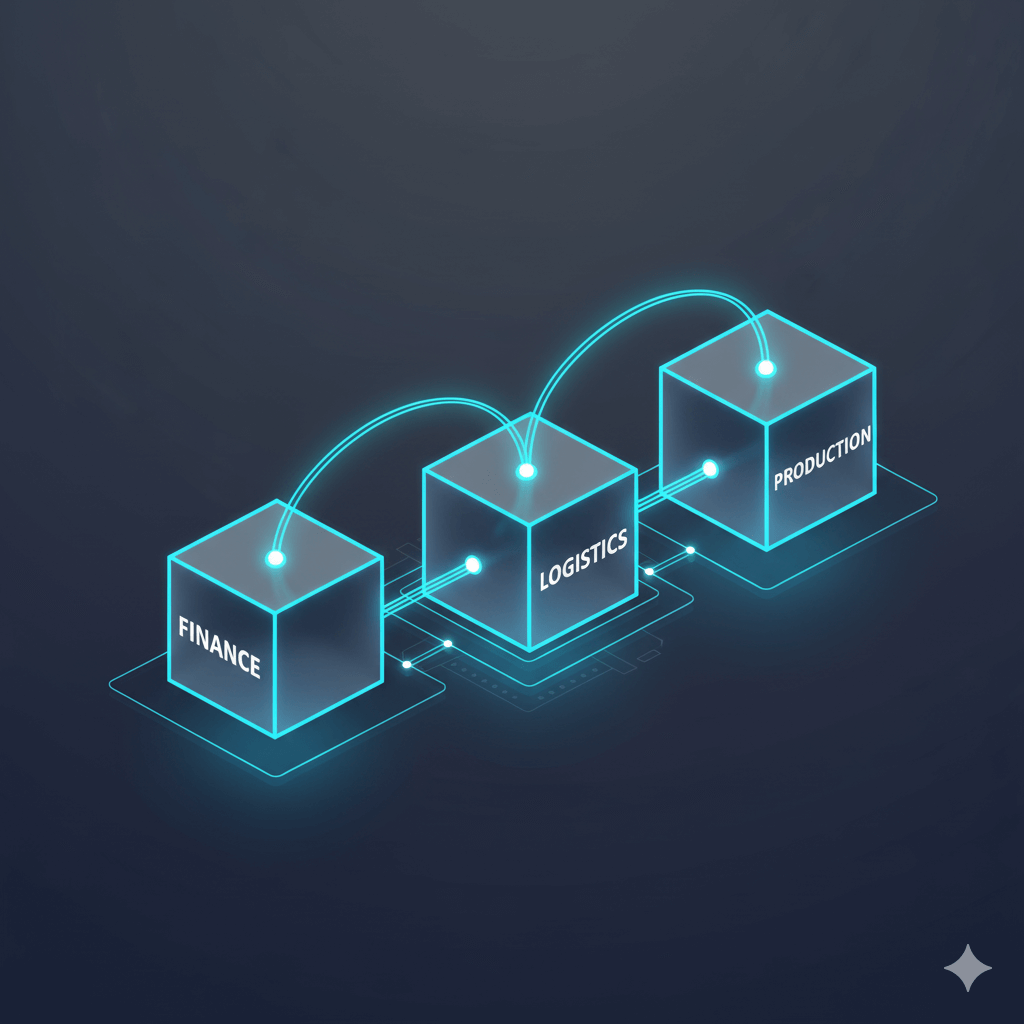

We connect ERP, SCADA, MES, CRM and e-commerce with secure APIs, events and end-to-end monitoring.

Data normalization, master catalogs, queues and retries.

Web-based orchestrator, connectors ready for SAP PI/PO, BTP, Odoo, SQL Server.

AI software for spare parts management.

An agent and spare parts catalog with intelligent substitutions (graphs & AI).

Visibility of integrations and SLAs with executive metrics.

Intelligent document ingestion to your ERP/ECM.

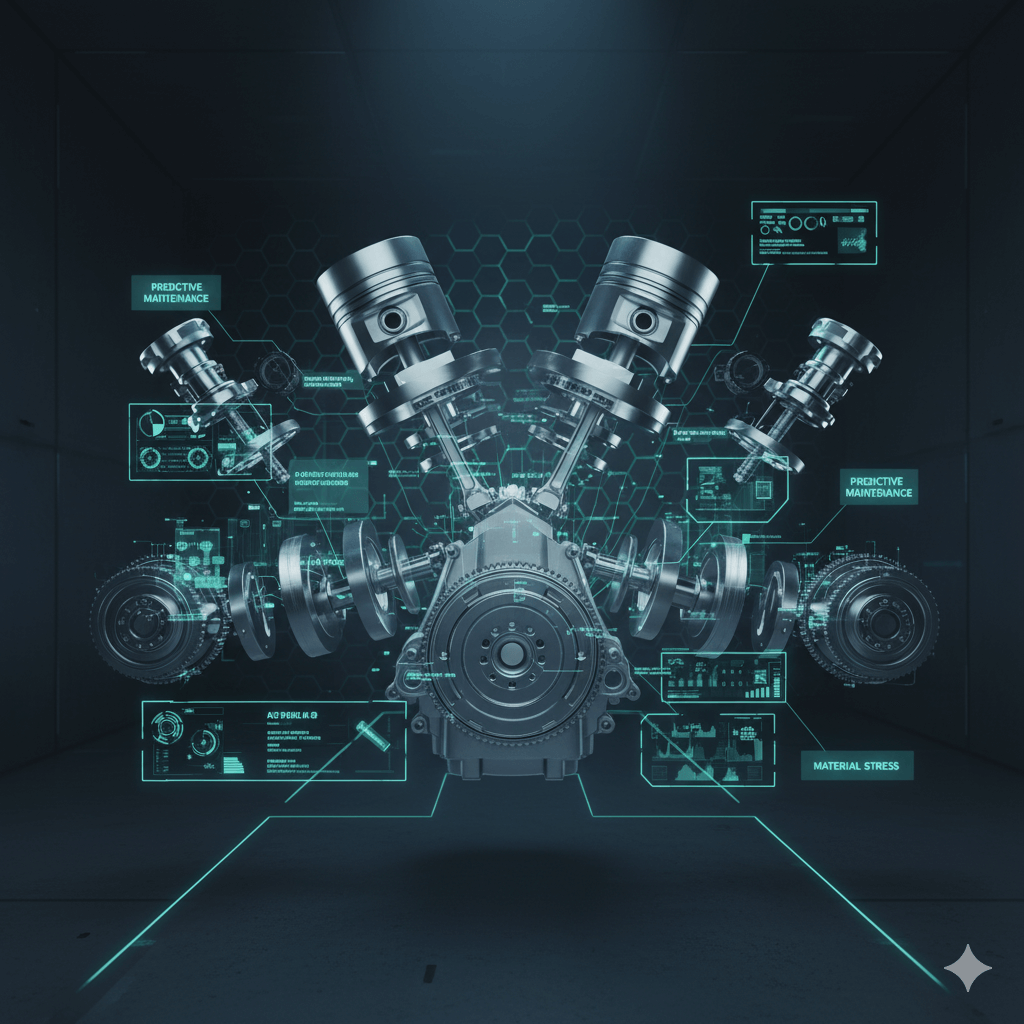

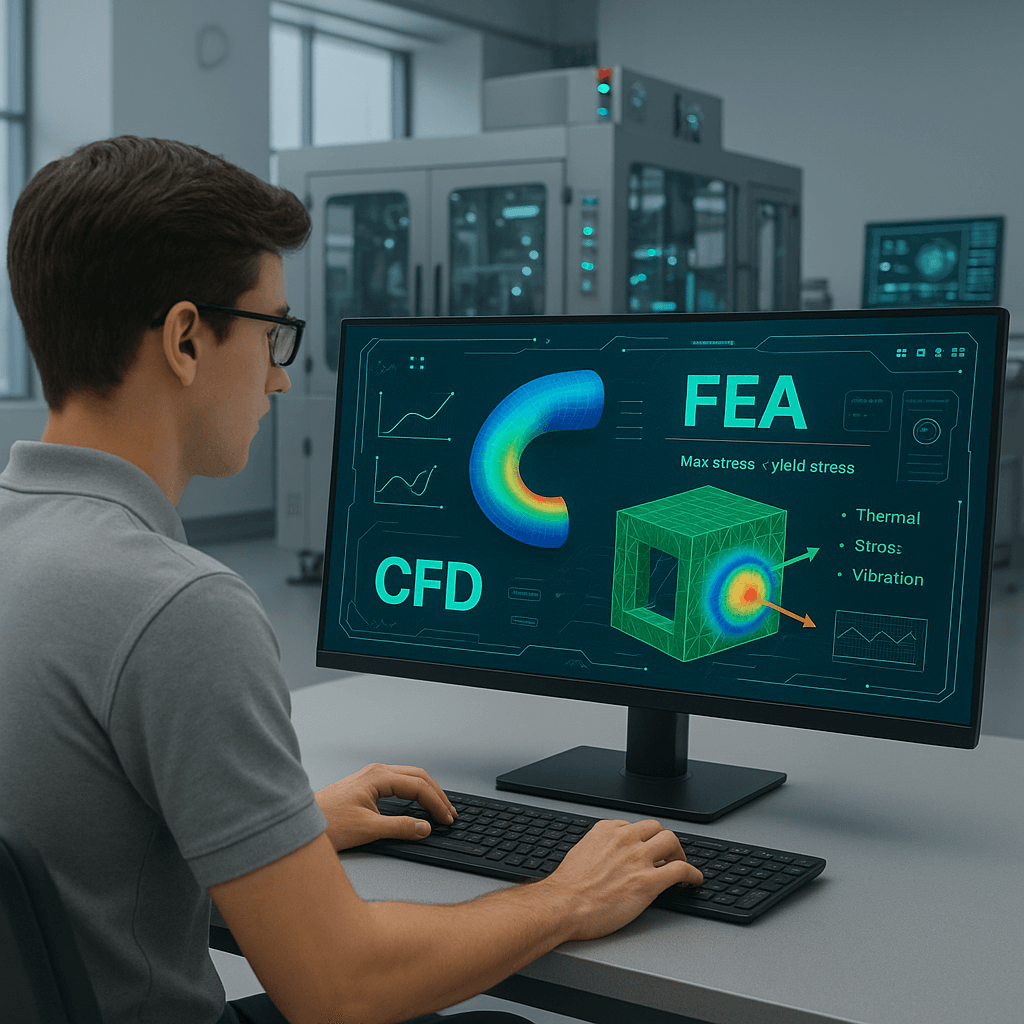

We simulate before executing and optimize product (geometry, topology, material strength).

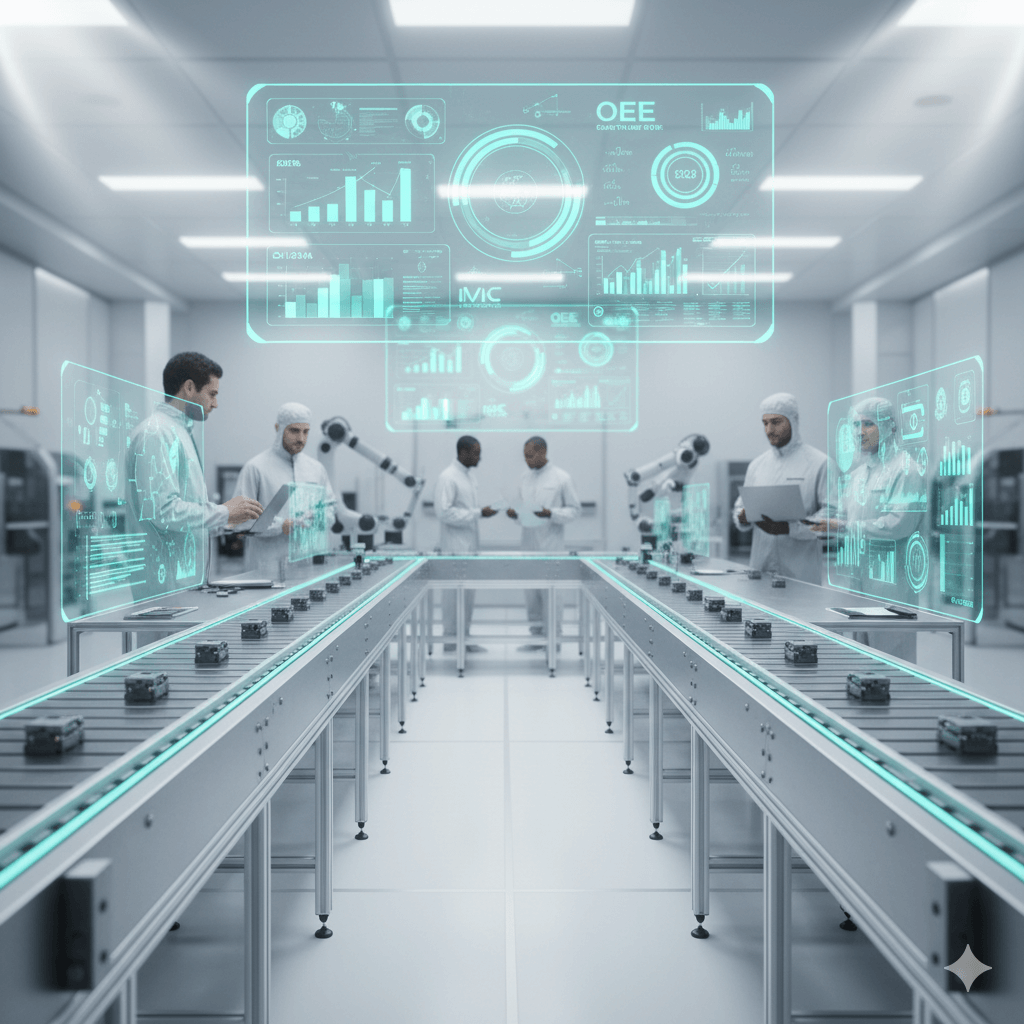

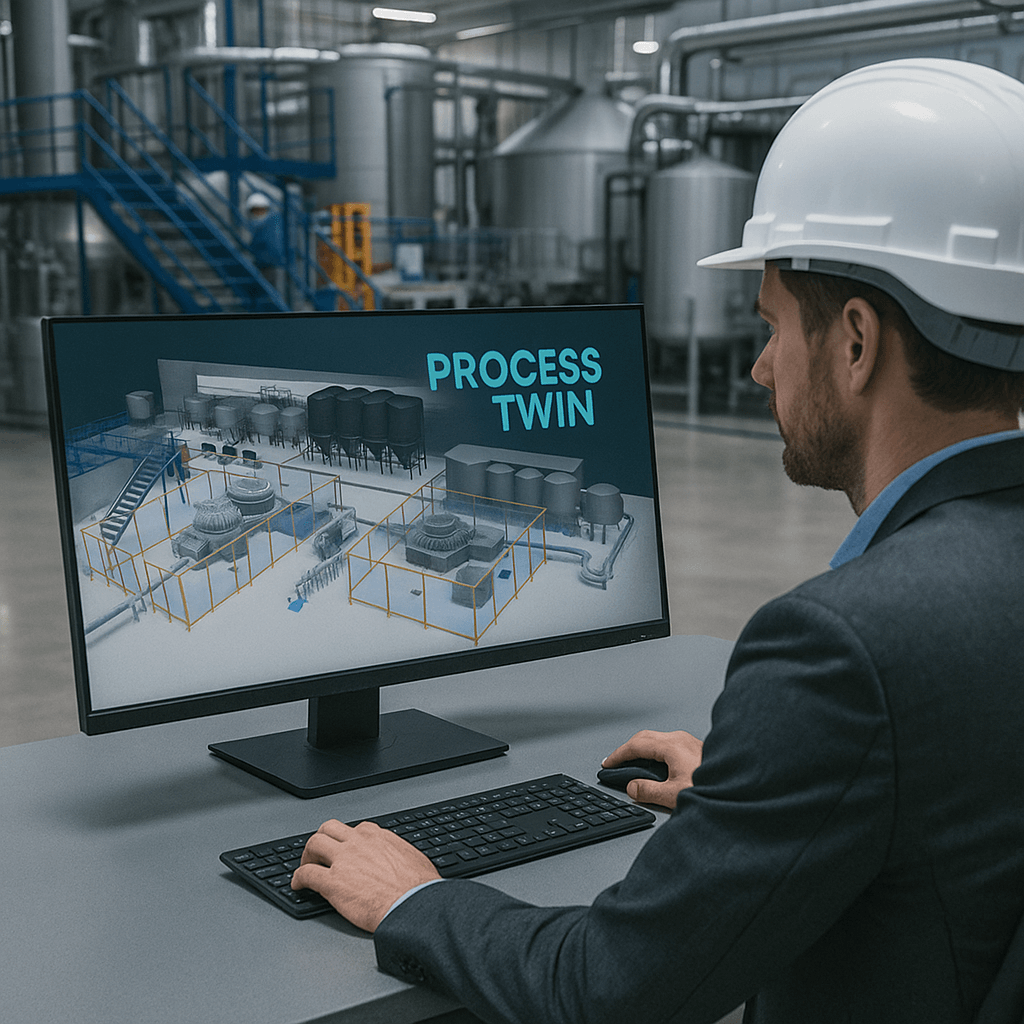

Digital production models that replicate real plant behavior to improve efficiency, anticipate bottlenecks and optimize resources.

FEM/CFD computational simulation, geometry optimization, stress analysis and thermodynamic & fluid dynamic performance.

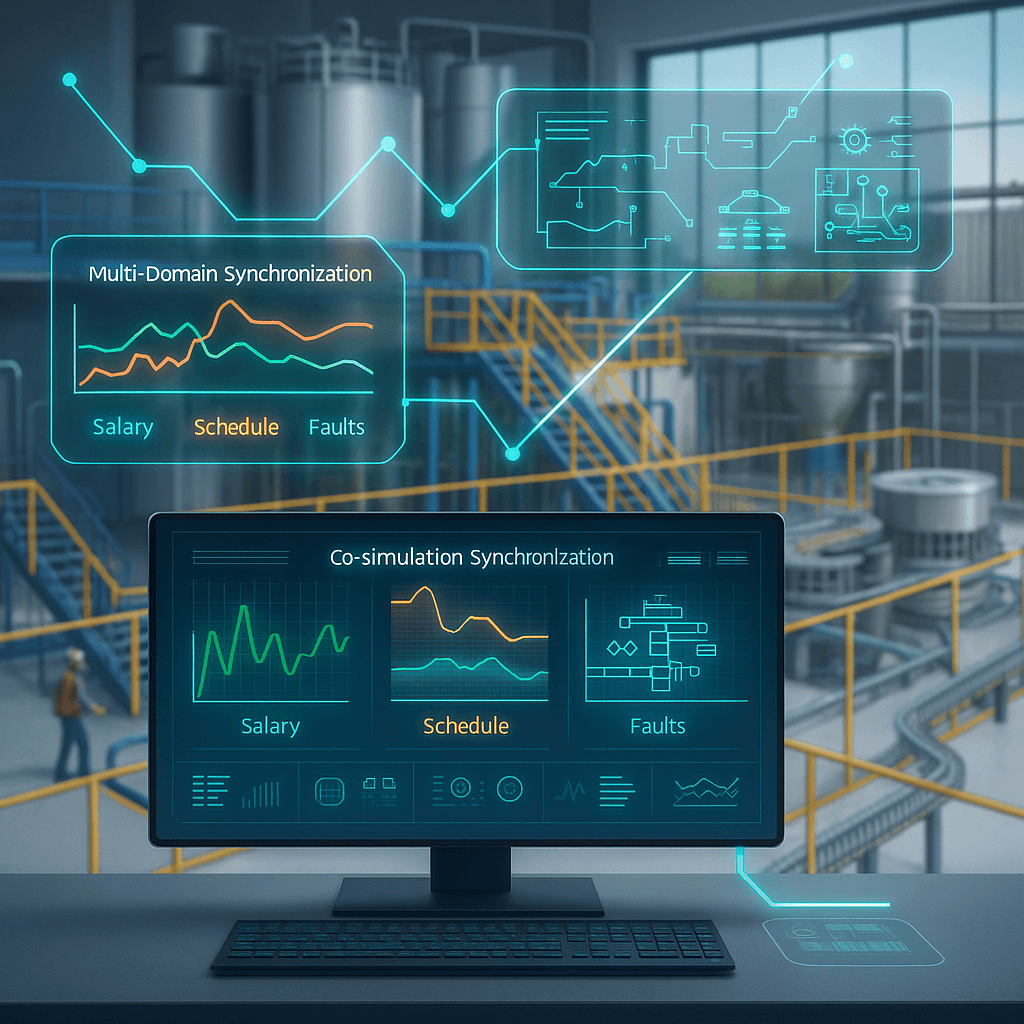

Integration between virtual simulations and the real control system (PLC/SCADA) to validate logic, synchronize processes and optimize operational performance.

Configuration of flows and automations with on-premise AI agents in your ERP. Automate repetitive tasks and ease decision-making.

Access Control, EAM, SoD analysis and audits. Controls for regulatory compliance and business continuity.

Security for ERP environments, access management, infrastructure protection, monitoring and incident response.

Advisory service based on industrial indicators to evaluate the current state and define a technology adoption plan that drives the transformation towards the Smart Factory.

We identify the main operational challenges and technological opportunities of your plant.

We apply the SIRI model to measure the digital maturity level of your organization.

An implementation roadmap by phases, aligned with your high-level strategic objectives.

We model economic, operational and technological impacts with results, projections and ROI estimates.

Measurable improvements with direct impact on your operation.

Increase in production capacity

Optimization of time and rework through workflow improvements

Energy optimization of processes

We drive industrial transformation through three strategic service lines: production process optimization, system integration and digital twins. We design solutions that integrate artificial intelligence, advanced analytics and automation to raise efficiency, reduce losses and accelerate decision-making.

As additional services, we offer the Operational Assessment —to diagnose technological maturity and plan the adoption of Industry 4.0— and solutions in ERP & Cybersecurity that strengthen business management and operational continuity.